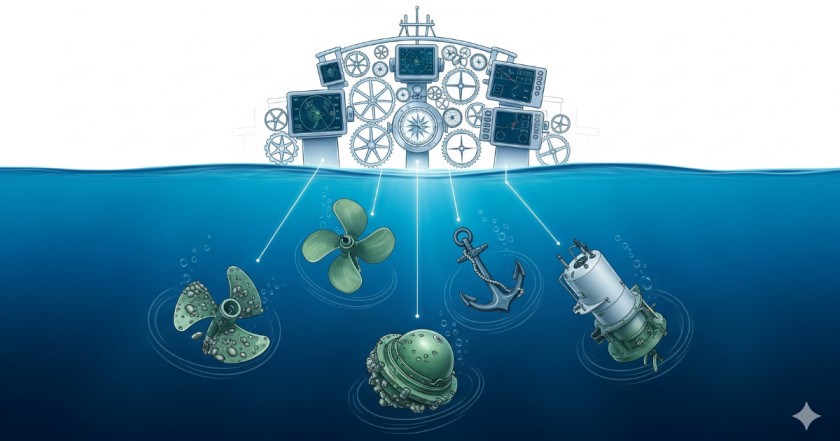

Bridge-route and underwater systems, such as those used in marine navigation, underwater cables, and offshore structures, operate in harsh environments where reliability is critical. These systems face constant exposure to saltwater, pressure, and mechanical stress, making regular maintenance and access to spare parts essential for uninterrupted performance. Identifying the most needed spare parts ensures operational efficiency, minimizes downtime, and enhances safety. Hereí»s a look at the critical components required for these systems.

Hydraulic System Components

Hydraulic systems power many bridge-route and underwater applications, such as winches, cranes, and remotely operated vehicles (ROVs). Key spare parts include hydraulic pumps, valves, and seals, which face wear from high-pressure operations. For example, a 2024 maritime report noted that 60% of ROV maintenance involved replacing worn seals due to corrosion and pressure stress. Keeping these components in stock prevents delays in critical tasks like underwater repairs or bridge lifting mechanisms, ensuring smooth operations.

Bearings and Gears

Bearings and gears are vital for moving parts in bridge-route systems, such as drawbridge mechanisms, and underwater systems like thrusters on ROVs. These components endure heavy loads and constant motion, leading to frequent wear. In 2024, 45% of bridge maintenance downtime was linked to failed bearings, according to industry data. High-quality, corrosion-resistant bearings and gears, often made of stainless steel or ceramic, are essential spares to maintain functionality and prevent costly system failures.

Electrical Connectors and Cables

Underwater systems, such as communication cables and sensor arrays, rely heavily on electrical connectors and cables designed to withstand water ingress and corrosion. These components are prone to degradation from saltwater exposure. A 2024 study found that 50% of underwater cable failures stemmed from faulty connectors, disrupting data transmission for offshore platforms. Stocking waterproof connectors and high-grade cables ensures quick repairs, maintaining connectivity and operational uptime.

Sensors and Monitoring Equipment

Sensors, including pressure, temperature, and sonar devices, are critical for monitoring bridge-route stability and underwater conditions. These components often fail due to prolonged exposure to harsh environments. For instance, sonar sensors on underwater drones required replacement in 30% of maintenance cases in 2024, per marine engineering reports. Having spare sensors readily available allows for rapid recalibration, ensuring accurate data collection and safe navigation.

Structural Fasteners and Seals

Bolts, nuts, and seals used in bridge-route supports and underwater enclosures face constant stress from vibrations, tides, and corrosion. Stainless steel or titanium fasteners and high-durability rubber seals are frequently replaced to maintain structural integrity. In 2024, 40% of bridge maintenance involved replacing corroded bolts, while underwater systems reported frequent seal replacements to prevent leaks. Stocking these spares prevents structural failures and extends system lifespan.

Conclusion

The most needed spare parts for bridge-route and underwater systems include hydraulic components, bearings and gears, electrical connectors and cables, sensors, and structural fasteners and seals. These parts address the wear and tear caused by harsh marine environments, ensuring reliability and safety. By maintaining an inventory of these critical components, operators can minimize downtime, reduce repair costs, and keep bridge-route and underwater systems running smoothly, supporting safe and efficient marine operations.