Marine engines are the backbone of ships and offshore vessels, directly influencing fuel consumption, operational costs, and environmental compliance. One critical component that plays a major role in engine efficiency is a hydraulic pump, such as the Abex Dension pump. By delivering precise control over propulsion, steering, and auxiliary systems, it ensures engines operate efficiently under varying marine conditions.

Role of Hydraulic Pumps in Engine Efficiency

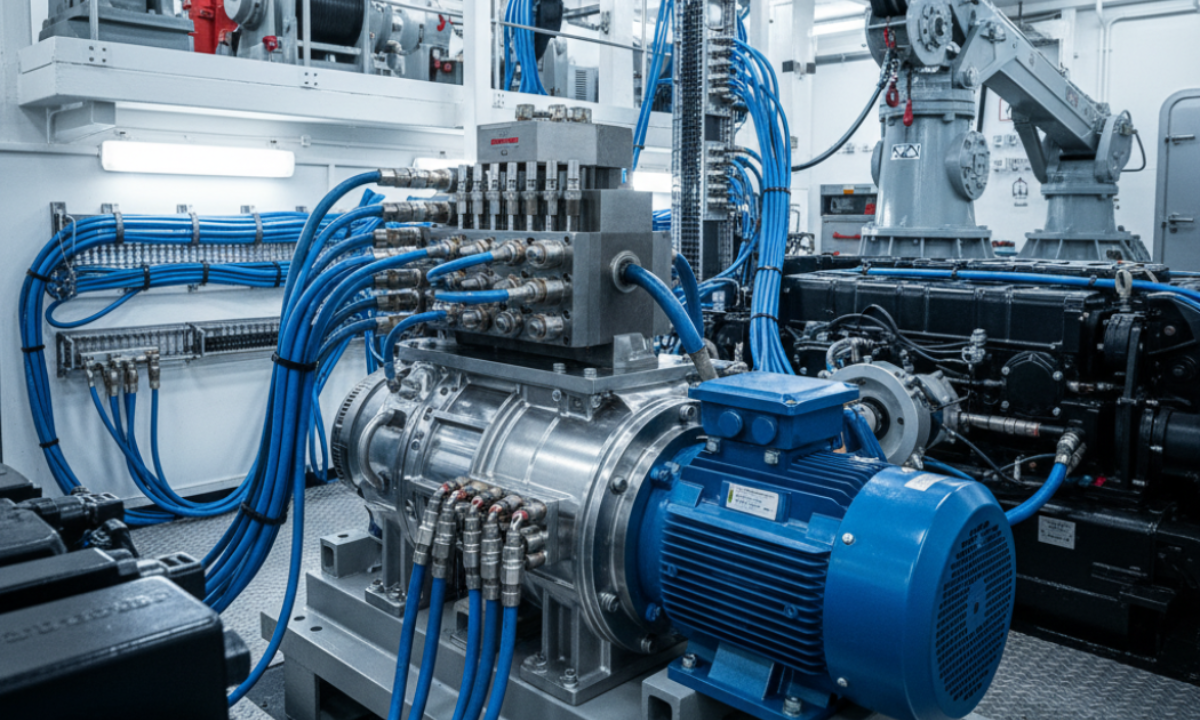

Hydraulic pumps convert mechanical energy from the engine into pressurized fluid power, which is used to operate steering systems, variable pitch propellers, stabilizers, and deck machinery. This precise energy transfer reduces mechanical losses and allows engines to maintain consistent performance without unnecessary strain.

In propulsion systems, hydraulic pumps adjust propeller angles in real time, keeping engines within their most efficient operating range. This prevents excess fuel consumption during acceleration, cruising, or heavy load conditions. By delivering power accurately, the system enhances the overall energy efficiency of marine engines.

Hydraulic pumps also allow for smoother and more responsive engine control, especially in challenging sea conditions. By maintaining stable pressure and flow, they reduce unnecessary load variations, which can otherwise cause the engine to work harder than needed, consuming more fuel.

Impact on Fuel Consumption

A well-maintained hydraulic pump allows for smoother engine operation and optimized fuel use. Accurate control of steering, stabilization, and propulsion systems reduces sudden load changes, minimizing fuel wastage and lowering emissions. This is particularly crucial for vessels operating on long ocean voyages, where fuel efficiency translates directly into significant cost savings.

Additionally, proper selection of hydraulic fluids and regular monitoring ensures minimal internal friction, which helps maintain consistent energy transfer within the system. By reducing mechanical losses, the pump ensures that every unit of energy generated by the engine is used effectively for propulsion and auxiliary functions.

Maintenance and Monitoring

Hydraulic pumps contribute indirectly to fuel efficiency through preventive maintenance and condition monitoring. Sensors can track pressure, flow, and temperature, alerting engineers to potential issues before they affect performance. Predictive monitoring allows crews to schedule maintenance proactively, preventing downtime and ensuring that the engine operates at peak efficiency.

Routine inspections of the pump, hydraulic lines, and associated components ensure that there are no leaks or blockages that could reduce efficiency. Even minor inefficiencies in the hydraulic system can lead to unnecessary fuel consumption over time, making maintenance critical for long-term performance.

Conclusion

Hydraulic pumps are essential for maximizing the efficiency and reliability of marine engines. By managing propulsion, steering, and auxiliary systems with precision, they help engines operate smoothly under varying loads, reduce fuel consumption, and maintain optimal energy use. Components like the Abex Dension pump provide dependable performance and high reliability, making them a critical part of modern marine hydraulic systems.

Integrating advanced monitoring systems and maintaining the pump properly ensures sustained efficiency, helping vessels achieve better operational performance while lowering environmental impact. Hydraulic pumps are not just components they are enablers of effective and cost-efficient marine operations. Check out Maritek Solutions for more marine machinery.