Marine diesel engines are complex systems where every component plays a critical role in maintaining efficiency, performance, and longevity. Among these components, the exhaust valve seat is one of the most crucial yet often overlooked parts. It forms the contact surface for the exhaust valve and ensures proper sealing during combustion, directly affecting engine efficiency, fuel consumption, and emissions.

The Role of the Exhaust Valve Seat

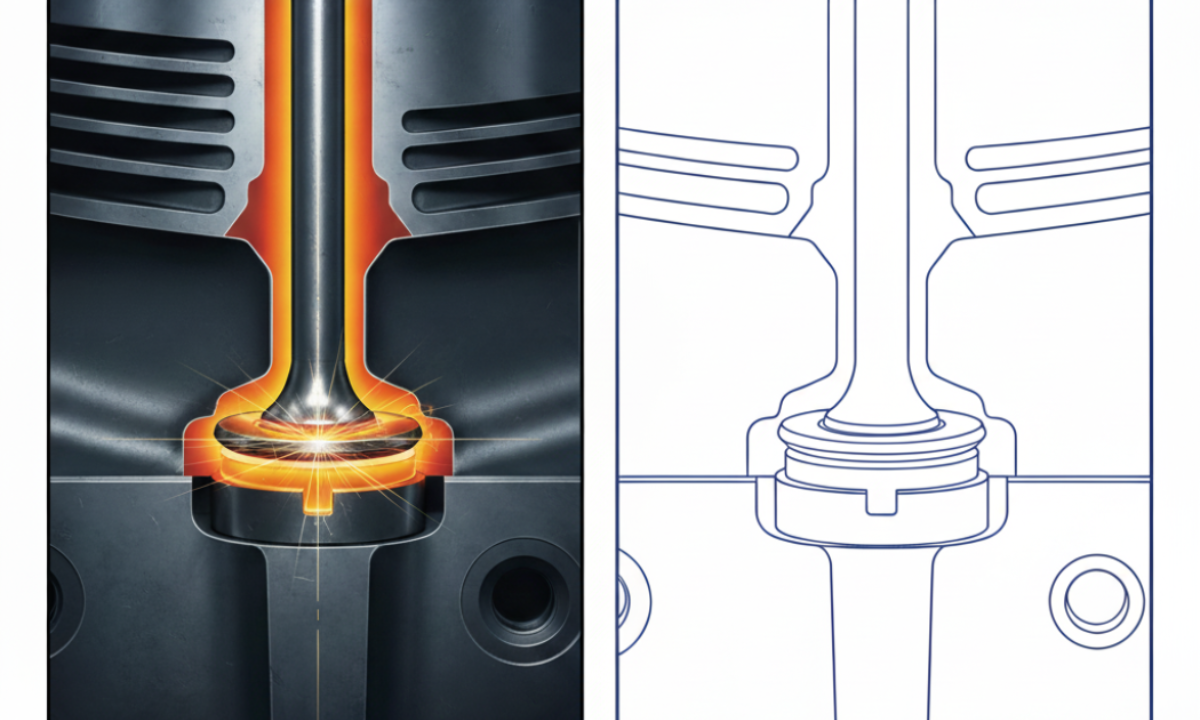

The exhaust valve seat provides a secure and precise surface for the exhaust valve to close against during the combustion cycle. This sealing prevents hot combustion gases from leaking into the cylinder head and maintains proper compression within the combustion chamber. Proper sealing is essential for optimal fuel combustion, consistent engine performance, and reduced emissions.

In addition to sealing, the valve seat facilitates heat transfer from the valve to the cylinder head. During operation, exhaust valves are exposed to extremely high temperatures. The valve seat acts as a heat sink, dissipating energy efficiently to prevent valve overheating, warping, or premature wear.

Impact on Engine Performance

A well-installed exhaust valve seat directly contributes to engine reliability and efficiency. If the valve seat is misaligned or worn, several performance issues can arise:

- Loss of Combustion Efficiency: Incomplete sealing allows hot gases to escape, reducing compression and lowering thermal efficiency.

- Increased Fuel Consumption: Engines compensate for lost compression by consuming more fuel to maintain output.

- Accelerated Component Wear: Escaping gases can damage the cylinder head, valve guides, and pistons over time.

- Higher Emissions: Poor combustion results in increased unburnt hydrocarbons and particulate matter, potentially causing non-compliance with marine environmental standards.

By maintaining proper valve seating, operators ensure smooth engine operation, consistent power delivery, and reduced environmental impact.

Maintenance and Inspection

Regular inspection and maintenance of exhaust valve seats are vital for sustaining engine performance. Engineers should monitor the seat for wear, pitting, cracks, or misalignment. Using OEM-certified components ensures that tolerances are maintained, and precision machining of the cylinder head helps achieve proper alignment. Condition monitoring tools can further detect early signs of valve seat degradation, allowing preventive action before performance issues occur.

Conclusion

The exhaust valve seat is a small but essential component in marine diesel engines, playing a critical role in sealing the combustion chamber, transferring heat, and maintaining overall engine efficiency. Proper installation, regular maintenance, and use of high-quality components ensure optimal fuel consumption, reduced emissions, and reliable engine performance. Understanding the function of the exhaust valve seat is key for marine engineers and fleet operators seeking long-term operational efficiency and durability.