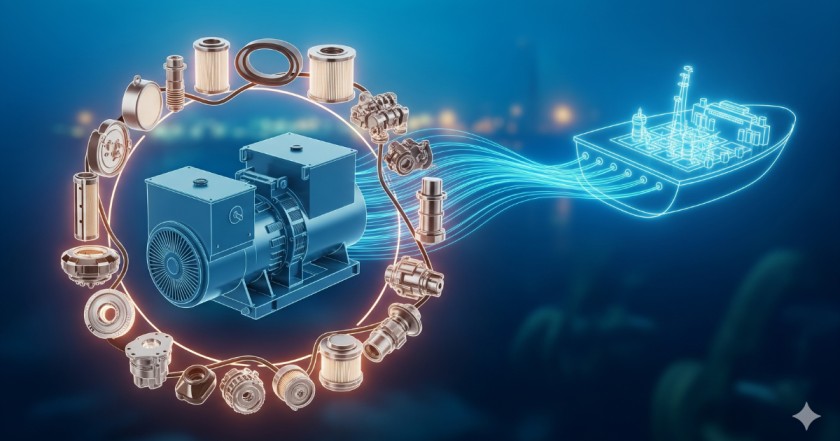

Marine vessels rely heavily on generators to power critical systems like navigation, communication, and propulsion, especially during long voyages or in remote offshore locations. Operating in harsh marine environments, generators face constant stress from saltwater corrosion, vibration, and heavy loads, making maintenance and spare parts essential for uninterrupted power supply. Having the right generator spare parts on hand ensures reliability, minimizes downtime, and enhances safety at sea. Hereí»s how these components support continuous marine power.

Ensuring Reliable Engine Performance

The engine is the heart of a marine generator, and spare parts like fuel filters, injectors, and gaskets are critical for maintaining performance. Fuel filters prevent contaminants from clogging the system, while injectors ensure efficient combustion. In 2024, 55% of generator failures on cargo ships were linked to clogged fuel systems, according to maritime maintenance data. Stocking these spares allows crews to address issues quickly, preventing power interruptions that could halt navigation or critical operations.

Maintaining Electrical System Stability

Marine generators power sensitive electrical systems, requiring stable components like alternators, voltage regulators, and circuit breakers. Alternators convert mechanical energy into electricity, and their failure can disrupt power to essential equipment. A 2024 study found that 30% of onboard power outages stemmed from worn voltage regulators. Keeping these spares readily available ensures quick replacements, maintaining consistent power output and preventing damage to navigation or communication systems.

Combating Corrosion and Wear

The marine environment, with its saltwater exposure and humidity, accelerates wear on generator parts like bearings, belts, and cooling system components. Corrosion-resistant bearings and high-durability belts are frequently replaced to prevent mechanical breakdowns. For instance, cooling system failures accounted for 25% of generator downtime in 2024, often due to corroded radiators or pumps. Stocking these spares ensures generators withstand harsh conditions, supporting continuous operation during extended voyages.

Supporting Rapid Repairs to Minimize Downtime

Downtime at sea can be costly and dangerous, especially for vessels far from port. Spare parts like starter motors, oil pumps, and turbochargers enable rapid repairs to keep generators running. A 2024 maritime report noted that vessels with comprehensive spare parts inventories reduced downtime by 40% compared to those without. Quick access to these components allows crews to address failures promptly, ensuring power for critical systems like refrigeration for perishable cargo or life-support systems on cruise ships.

Enhancing Safety and Compliance

A reliable power supply is vital for safety and regulatory compliance in marine operations. Generators power emergency systems, such as fire pumps and lifeboat davits, which must function without fail. Spare parts like relays and sensors ensure these systems remain operational. In 2024, 70% of vessels passing safety inspections had well-maintained generators with spare parts on board, per industry audits. Maintaining these components helps meet standards like SOLAS (Safety of Life at Sea), avoiding penalties and ensuring crew safety.

Conclusion

Generator spare parts, including fuel system components, electrical parts, corrosion-resistant materials, and repair essentials, are vital for supporting continuous marine power supply. By enabling reliable performance, rapid repairs, and compliance with safety standards, these spares minimize downtime and enhance vessel safety. For marine operators, maintaining a robust inventory of generator spare parts is a strategic investment to ensure uninterrupted power and operational success in the challenging maritime environment.